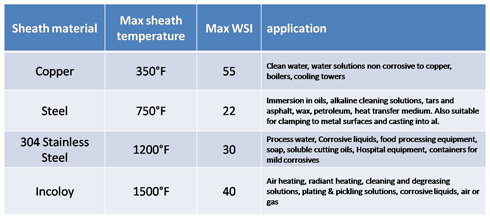

There are many different sheath materials available. The most important factor is the material or fluid that will be in direct contact with the heater. In many situations, different sheath materials could be used. But in some instances, you don’t have a choice to what sheath material needs to be used. (Example: Hydrofluoric Acid requires PTFE “Teflon” coated heat elements) If the specs calls only for stainless steel, make sure which one (Example: 304, 310, 316 or 321; see below) you need. Our technical staff can give you recommendations which sheath material to use for which application.

Applications

Stainless steel sheath materials:

Other sheath materials used:

Aluminum:

Mainly used for comfort heating. Fins are used to increase surface area. Maximum recommended watt density in air is 30 WSI with fins, 6 WSI without fins.

Incoloy:

Inconel was the material most widely used for air heating applications, but has been replaced by Incoloy 800 because of its cost. (Inconel still finds use in areas of extremely high temperatures 1700°F + and corrosive environments; It is composed of Nickel, Chromium, plus trace elements.) Incoloy is also gaining popularity as a sheath material for water heating elements.

Titanium:

This material is used primarily in immersion heating of highly corrosive materials such as acids. It is the most costly of the sheath materials mentioned.

|